JPE Industry Insights | High-Pressure Gas Booster Pumps Enhancing Leak-Tightness Testing and Low-Leakage Performance

2025-04-18

Industry Knowledge Popularization

In today’s industrial world where high-pressure technologies are widely applied, “low leakage rate” is no longer just part of product inspection—it has become a core indicator of overall system safety, efficiency, and sustainability. With strong expertise in high-pressure technology R&D, JPE is dedicated to providing stable and reliable low-leakage fluid solutions, becoming a key support for industrial advancement across sectors.

Why is “Low Leakage Rate” More Important Than Ever?

As equipment grows more complex and performance demands increase, even the slightest leak can cause product failure, testing errors, or even safety incidents. Take airtightness and pressure resistance testing for example—when the tested subjects include pressure vessels, fluid systems, or fuel cell modules, the accuracy and stability of the test directly reflect product quality. And all this depends on testing equipment that is virtually “leak-free.”

JPE’s gas boosters are specifically designed for high-precision testing, with airtightness prioritized at every stage of design and manufacturing. Whether it’s the internal sealing structure, material selection, oil-free lubrication design, or machining precision of the pump body and joints, all aspects center around micro-leakage control—ensuring stable operation even under high pressure conditions of 70 MPa (around 700 Bar).

The Ideal Partner for Precision Testing

Hydrogen, one of the most promising clean energy sources today, is quickly being adopted in fuel cells, hydrogen vehicles, and energy storage systems. But due to hydrogen’s extremely small molecules and strong permeability, the requirements for airtightness in sealing components and gas delivery systems are far stricter than for ordinary gases.

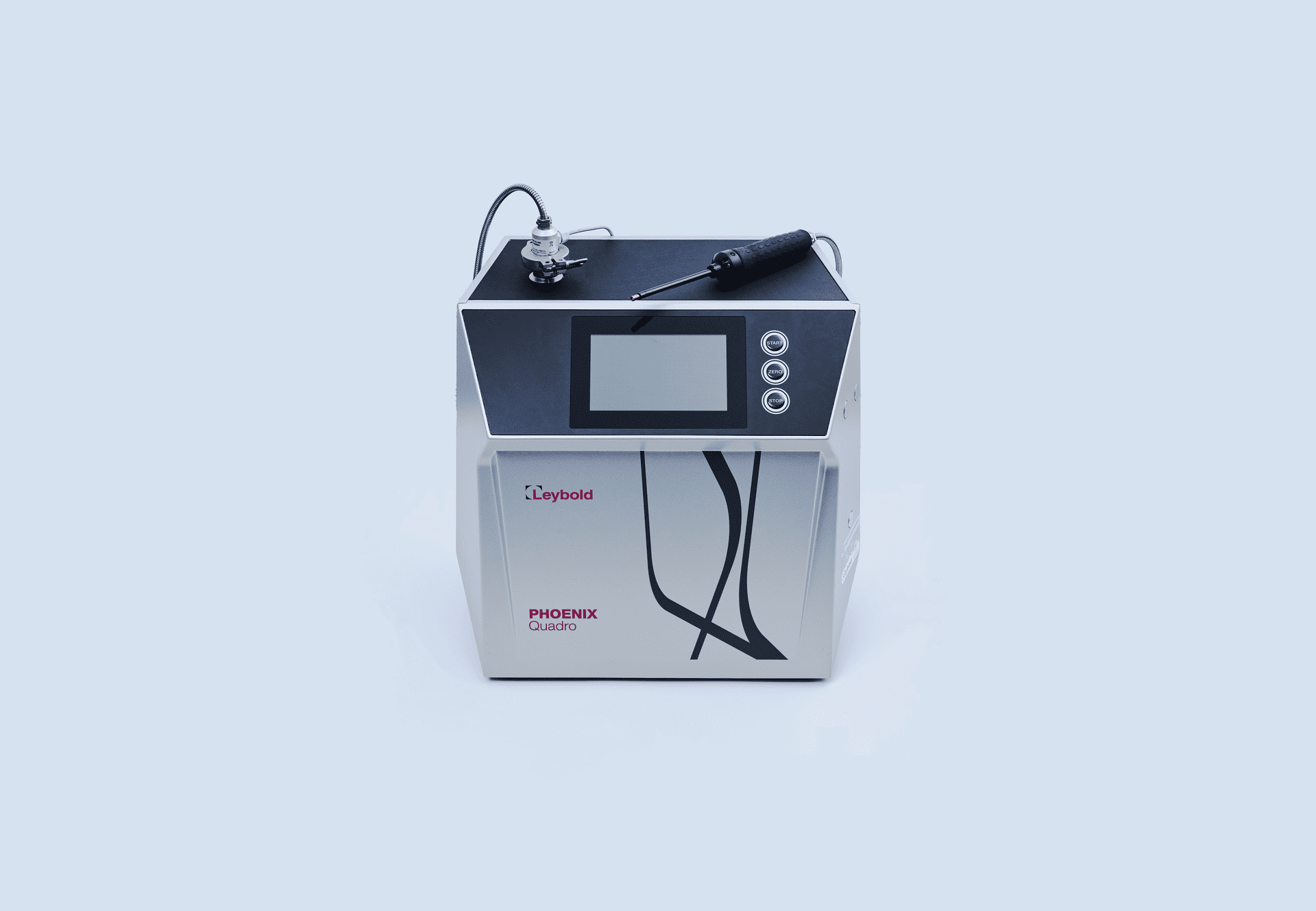

One major application of high-pressure pumps is performing airtightness testing with helium mass spectrometers. In this process, the purity and output stability of the test gas directly affect the accuracy of the results. JPE has introduced a high-pressure pump testing mechanism in its factory, simulating verification environments with high-pressure hydrogen for key products like joints and valves. This ensures excellent airtightness and reliability in real-world applications. Every product that passes testing not only demonstrates JPE’s strict manufacturing standards but also provides a solid guarantee for the safe operation of hydrogen systems.

The Unsung Hero Behind the Hydrogen Industry

The development of the hydrogen industry requires not only policy and systemic support but also precise coordination of key technologies and equipment. Based on its newly added high-pressure pump production capabilities, JPE focuses deeply on the high-pressure fluid domain, continuously refining low-leakage system solutions, and closely aligning with application needs—injecting powerful momentum into the industry's growth. From fuel cell module testing, hydrogen storage vessel airtightness verification to high-pressure hydrogen transportation, JPE helps clients establish efficient, controlled, and safe operational processes.

A high-pressure pump is not just a standalone device—it is the core driving force of the entire airtight testing and high-pressure simulation system. Besides offering a wide range of product options, JPE can also provide customized solutions tailored to clients’ testing pressures, gas characteristics, and site conditions. From design and manufacturing to testing and after-sales service, the professional JPE team provides full support, delivering a stable and reliable technical backbone for industry partners.

High-Pressure Technology × Precision Manufacturing = The Best Practice for Low Leakage Rates

Only through strict quality control can we effectively pursue the lowest leakage rates and build a solid foundation for high-pressure testing and airtight applications. Facing increasingly demanding industrial challenges, JPE relies on stable and reliable technical expertise and precision manufacturing experience to become a trusted high-pressure equipment supplier for many industry partners. Looking ahead, JPE will continue to strengthen compatibility with clean energy applications like hydrogen and meet airtightness requirements—working hand in hand with clients to support the steady development of the hydrogen industry.